Projects

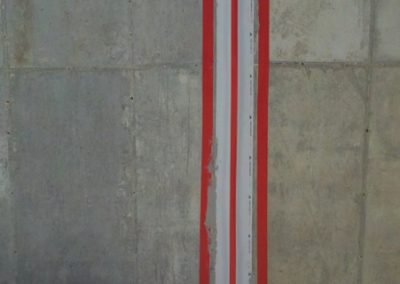

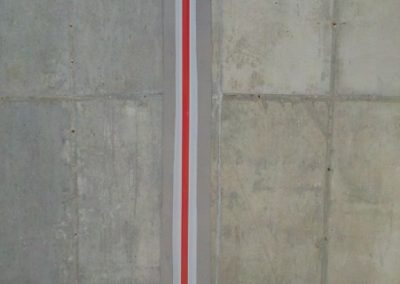

Active Joint Sealant

This retaining wall is part of a large secondary containment basin for a chemical tank. The joints actively move throughout the day due to thermal cycles, a poor foundation, and ground vibrations from nearby railroad tracks . A rigid joint sealant was not feasible. With this membrane method, expansion and contraction up to 2.5″ is allowed with no failure of the joint sealant or risk of chemical bypass should a leak occur.

Balcony Edge Removal and Replacement Grout

These balcony edges were severely deteriorated due to reinforcing steel being too close to the surface of the slab. The buildings location on the beach allowed salt water to make its way into the slab, corrode the rebar, and spall off the outer edge. In doing so, the guardrails that were attached to the edge were rendered ineffective. After replacing the damaged edge with grout, new handrails could safely be anchored to the balcony.

Balcony Overhead Spalling Grout Repair

The balconies on this building were deteriorated to an advanced degree. Severe spalling had occurred due to salt from the environment penetrating the slabs and corroding the reinforcing steel. After removing the deteriorated rebar and hand applying vertical repair grout, a coating was applied to seal the slabs and repairs from further salt intrusion.

Column Repair Grout and Injection

This column had poor consolidation of concrete during its initial pour resulting in a “honeycomb” area that failed as additional floors were poured on top of it. A combination of epoxy gel injection and vertical repair grout were used to regain integrity of the column.

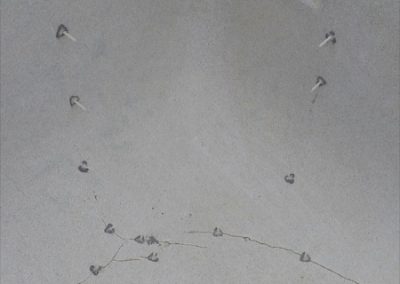

Concrete Pool Epoxy Injection

Concrete pools commonly crack because there is no expansion joint providing the concrete a place to move during the curing process. Typically, after cracking has occurred, epoxy injection can be used to restore integrity to the pool and re plastering of the cracked areas will take place.

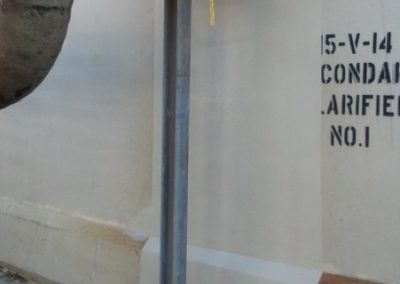

Concrete Tank Grout Repair

This concrete tank had steel reinforcing bands for support. The pipe penetration allowed water to access the bands and corrode them over time. As steel corrodes, it expands, spalling off more concrete allowing more water to come in. It is a compounding problem. This spall was cut out to sound concrete, the reinforcing bands were cleaned and coated in corrosion inhibitor, and the area was formed and poured with structural grout. The pipe penetration was sealed with polyurethane grout to eliminate future issues.

Concrete Tank Pipe Penetration Sealant and Urethane Grout Sealant

This pipe penetration was the initial reason for a spall occurring on the wall under it. Water was bypassing the pipe flange and corroding the steel reinforcing bands of the tank. After the spall was repaired, polyurethane grout was pumped behind the flanges and into the space around the pipe penetrating the wall. The grout expanded and cured forming a closed cell, flexible, durable seal.

Elevator Pit Leak Stop Urethane Grout

A portion of this elevator mechanism penetrated the bottom of the concrete elevator pit. Seasonally, ground water would make its way around the mechanism and flood the pit, interfering with the elevators operation. A hole was drilled through the floor of the pit and polyurethane grout pumped through it. The foam seen in the photo is the grout reacting with groundwater, expanding up through the channels that water entered the pit, and curing therefore sealing the pit.

Foundation Installation

This foundation was installed to mount a high speed spinning material separator. Due to poor subsoil, auger cast pilings were installed. Pile caps were poured on top of the pilings with anchor bolts laid out for super structure anchoring. The slab was poured with a retaining curb and sloped towards a drain for easy cleanup.

We're Ready to Solve Your Concrete Problems

We've been doing this since 1984. That's a long time. We're concrete repair experts. Call us. We'll be right up front with our solution and project cost.